Manufacturing

Unlock the full value of energy flexibility. Create a revenue-generating asset!

Demand Response programs are implemented by utility companies to encourage customers to reduce their electricity consumption temporarily during peak periods. Demand Response participation through Enersponse is completely free of charge, with no fees or penalties involved.

Demand Response for

Manufacturing Facilities

As society becomes increasingly conscious of its environmental impact, manufacturing facilities are taking proactive measures to manage their energy consumption and minimize their carbon footprint. At Enersponse, we help manufacturing clients achieve their maximum energy reduction goals by assisting them in enrolling and participating in demand response programs and tapping into financial incentives. Enersponse securely connects to the facilities existing controls and ensures seamless support for a sustainable power grid during peak demand periods.

Seamless Integration for Effortless Demand Response

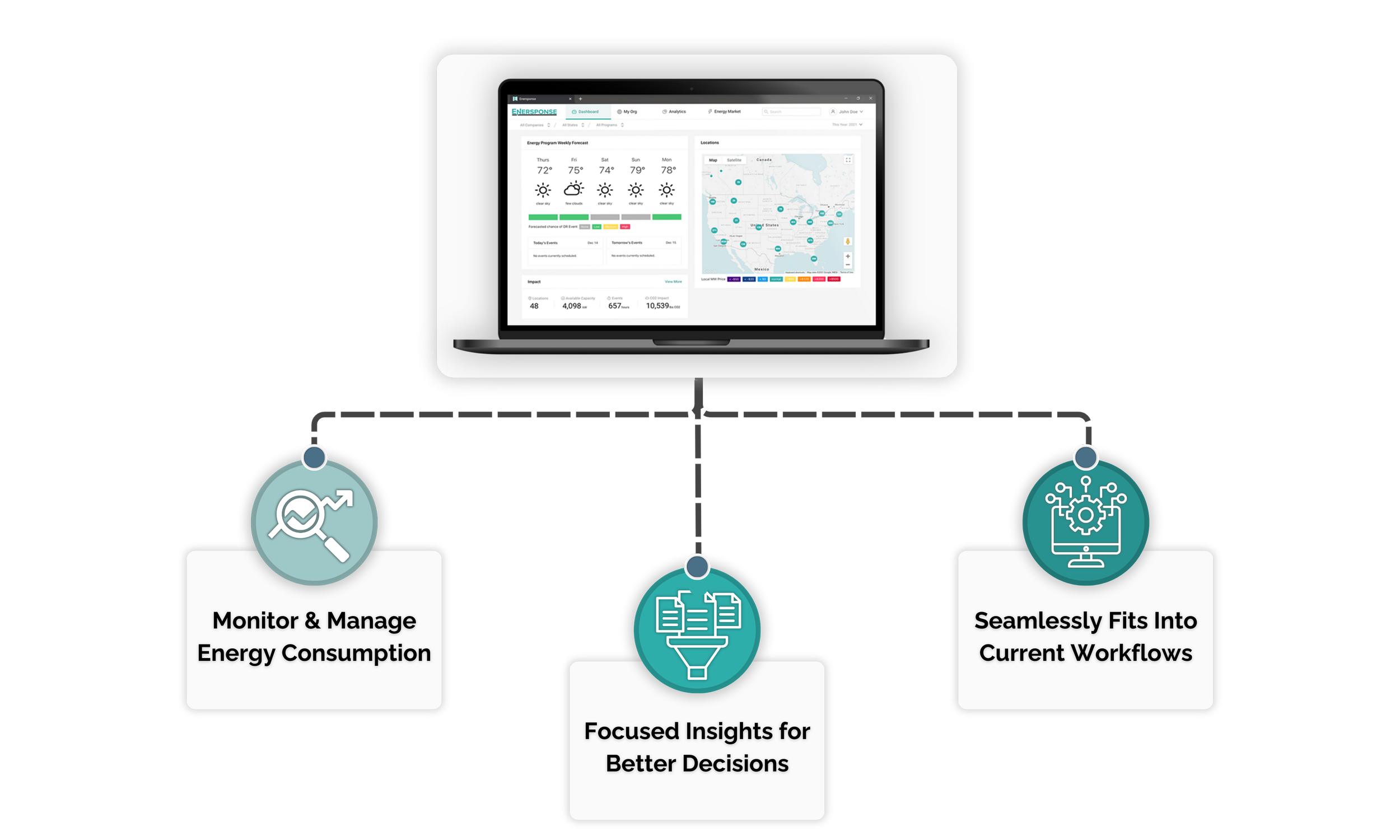

Our intuitive Demand Response Management System (DRMS) integrates with your controls, delivers event notifications in advance and provides comprehensive carbon reporting. We tailor participation to your batch schedules, VFDs, and critical equipment workflows with advanced notifications for optimal participation.

How Enersponse Supports Manufacturing

We understand that manufacturing facilities face intense operational demands—from batch production and precision equipment to rising energy costs and downtime risks. Manufacturers benefit significantly from leveraging demand response programs with Enersponse to offset costs and drive efficiency.

Here’s how we support manufacturing clients:

Demand Response (DR): Enroll in demand response programs to reduce load during peak demand events, earning substantial incentives while maintaining critical operations.

Automated Demand Response (ADR): Let our platform automate participation through your existing controls—no manual shutdowns or production delays required.

Data-Driven Insights

Wwe prioritize an in-depth analysis of your unique energy usage patterns. Unlike traditional approaches that rely on estimates, we use actual operational data to:

Identify opportunities

Tailor strategies

Deliver reliable results

Why choose Enersponse for your manufacturing facility?

-

Reduce energy cost and get paid to support grid reliability while maintaining operational reliability.

-

Optimize elevated water storage, redundant pumps, tank levels, and booster stations with precision.

-

Make informed decisions based on real-world data, not guesses.

-

Receive notifications in advance to prepare your facility for curtailment.

-

Utilize backup generators (where applicable) to ensure uninterrupted operations.

Curtailment Strategies Tailored to Your Operational Needs

-

On-Site Generation

Keep production running by switching to backup generators during peak demand events.

-

Compressed Air Optimization

Temporarily lower system pressure to reduce energy usage without impacting tool performance.

-

HVAC Controls

Optimize facility temperature setpoints during peak demand without compromising comfort.

-

Redundant Equipment Shutdown

Power down idle machinery or non-essential lines to reduce load without affecting throughput.

Future-Proof Your Energy Strategy

Energy market economics are shifting rapidly, and flexibility is key. Enersponse provides the agility and access you need to capitalize on evolving opportunities—without the complexity.

Ready to monetize your assets? Let’s build the future of energy together. Get in Touch!